Industries

Automation technology — Intelligent HMI components for efficient processes

In automation technology, precise and reliable HMI components are essential for controlling complex processes and designing them efficiently. At EP Electronic Print, we develop customized solutions that are specially tailored to the requirements of modern automation systems. Our HMI systems offer maximum precision, robustness and user-friendliness to optimally support processes in industry, manufacturing and logistics.

Areas of application in automation technology

Our HMI components are used in numerous areas of automation technology, including:

Special requirements and features

Automation technology is mainly concerned with capital goods that have to be durable, productive and cost-efficient. The most important performance features and requirements for our HMI systems can therefore be listed as follows:

Protection class IP65 or higher

Input systems in automation technology have special requirements in terms of reliability and durability. To prevent malfunctions due to the ingress of solids or liquids, our input systems are normally designed with closed surfaces. Ideally, the IP-Schutzklasse 65 gem. ISO EN 60529 recommended.

Resistant to oil and cleaning agents

Our HMIs or multi-touch displays are suitable for use in cleanroom environments as well as particularly harsh industrial environments. Whether highly alkaline cleaning agents, disinfectants or even oil, the resistance of our HMIs and the individual materials remains at the highest level(DIN 42115).

Design 24/7 operation

Productivity and reliability are two of the most important features and requirements in automation technology. Due to the increasing degree of automation, devices and systems are also in operation around the clock, which is precisely why the components used are so important. Careful selection of manufacturers and the right design are the decisive criteria here.

Long-term availability of the functional components

The demands on quality management are constantly increasing and have led to increased application safety. If problems do occur despite risk management measures, complete traceability of the functional components is required in order to analyze problems accurately. We can provide you with the necessary data at serial number level.

Protection against liquids

Thorough cleaning and disinfection of most devices and systems is always necessary in automation technology as well as in most industries. The systems should therefore be as robust as possible and completely resistant to the penetration of cleaning agents and disinfectants, oil, steam or water. For this reason, we would generally recommend at least the IP-Schutzklasse 65 gem. ISO EN 60529 recommend.

Electromagnetic compatibility — EMC according to industry standards

In order to avoid various external disturbances, systems or devices must be designed in accordance with EMC requirements, as described in detail in DIN EN 61004–4, for example. The selection of suitable mechanical and electronic hardware plays a very important role here. The main objective is, of course, to avoid both conducted and field-bound interference as well as dynamic or static interference.

Usability with gloves

In many areas of automation, especially in industry, it is necessary to work with gloves. However, this is not necessarily helpful when operating a touch system. To ensure smooth operation of the touch panel, it is therefore important to adjust not only the sensitivity but also the entire touch system to the various environmental conditions, such as electromagnetic interference.

Impact resistance

In addition to mechanical resistance, the shock resistance of the HMI/touch display is a very important feature. In EN 60068–2‑27, the resistance of a prototype to non-repetitive or repetitive shocks with a specified degree of severity is determined. The most common methods of achieving greater shock resistance in HMIs include glass tempering, optical bonding and mechanical bonding.

Manufacturing

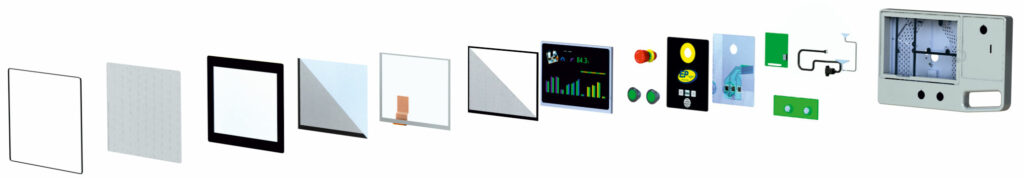

With over 25 years of experience with HMIs in the automation and mechanical engineering sector, we can offer you short development and fast delivery times. From multi-touch displays with foil or glass surfaces, classic membrane keyboards, housings or front panels made of metal or plastic to web panels for decentralized monitoring, we can provide you with everything from a single source.

Why EP Electronic Print?

At EP Electronic Print, we rely on state-of-the-art components and technologies to develop innovative and customized HMI solutions.

Do you have any questions or would you like to find out more about our HMI solutions?

Our team will be happy to advise you and work with you to find the best solution for your project. Use our contact form or call us directly — we look forward to hearing from you!

Non-binding contact request

Am Weidegrund 8 & 10

82194 Gröbenzell Technische Anfragen:

Telefon: +49 (0)8142 /420896–20

E‑Mail: projekte@ep-electronicprint.de Allgemeine Anfragen:

Telefon: +49 (0)8142 /420896–0

E‑Mail: info@ep-electronicprint.de